Products >> Extrusion blow molding machine >>

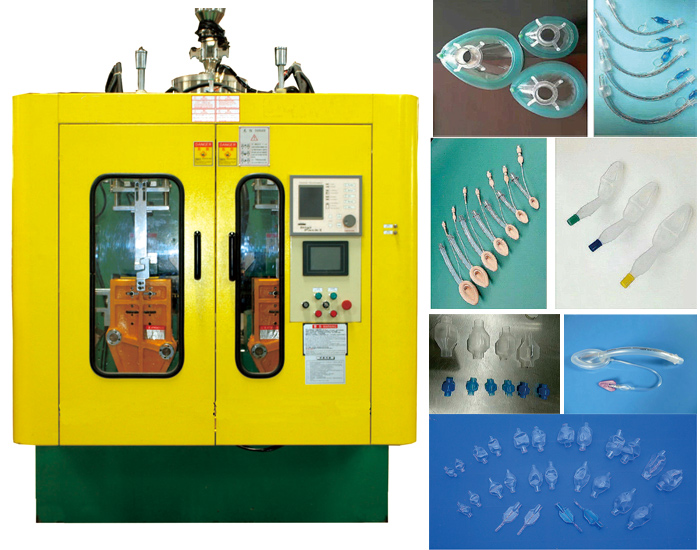

Medical Consumables Blow Molding Machine

- Product No.:202365172636

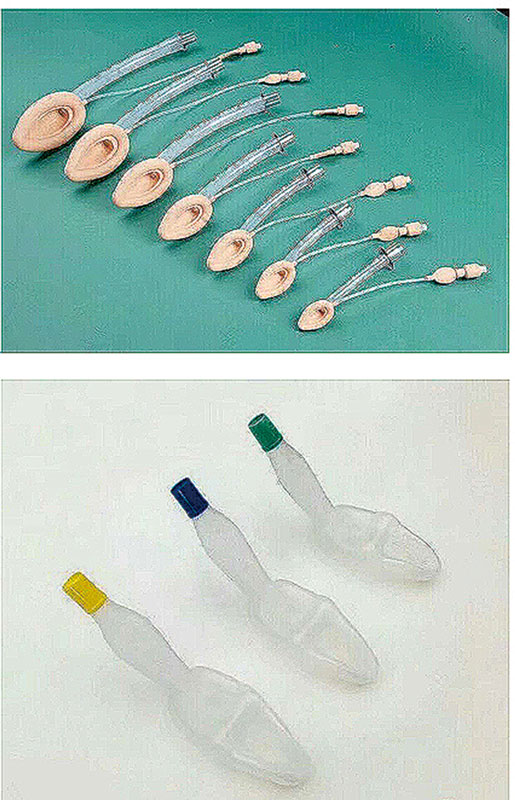

Product use: PVC mask,Medical balloon,Reagent dropper,Test bar

Single/Double Station

Single/Double/Triple/Quadruple...8 Head

Production Volume:2ml~1L

Multilayers: Co-Extrusion 1-6 Layers

Multi cavities: 1~6 cavities

Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion Material product

Introduction:

The Medical Consumables Blow Molding Machine is an advanced device specifically designed for the production of medical consumables through blow molding. It combines PLC computer control and a user-friendly human-machine interface (HMI) for efficient, precise, and reliable manufacturing solutions in the medical industry.

Key Features and Advantages:

High Automation: Equipped with a PLC (Programmable Logic Controller) computer control system, this blow molding machine enables precise control and monitoring of the entire production process. This ensures product consistency, quality stability, and improved production efficiency.

User-Friendly HMI: The equipment is equipped with an intuitive and user-friendly human-machine interface, allowing operators to easily configure, monitor, and adjust the machine. This simplified interface enhances operational convenience and increases operator efficiency.

Versatile Production Capability: The Medical Consumables Blow Molding Machine is adaptable to various types and sizes of medical consumables production requirements. By adjusting the molds and setting parameters, it can produce a wide range of medical consumable products, such as medical balloons and reagent droppers.

High Quality and Hygiene Standards: This machine employs advanced blow molding technology to manufacture products that meet stringent quality and hygiene standards in the medical industry. It utilizes medical-grade materials and undergoes strict production control to ensure product cleanliness and safety.

The combination of PLC computer control and a user-friendly HMI makes the Medical Consumables Blow Molding Machine an ideal choice for medical consumables production. It offers high automation, precision, and reliability, catering to the medical industry's demand for high-quality and efficient manufacturing processes.

Products Category

Latest News

Contact Us

Name: Ms.Apple

Tel: +86 76986298860

Mobile: +8613528556448

E-mail: [email protected]

QQ: 332128783

WeChat: +8613528556448

Whatsapp: +8613528556448

Add: 121 Junfa 3rd Road, Dongkeng Town, Dongguan City, Guangdong Province, China

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online